Additel 681

Digital Pressure Gauge

- Pressure ranges to 60,000 psi (4,200bar)

- 0.02%, 0.05%, 0.1% or 0.2% FS or 0.1% RD accuracy

- % pressure indication with fan-shaped graph scale for visual reference

- Fully temperature compensated accuracy

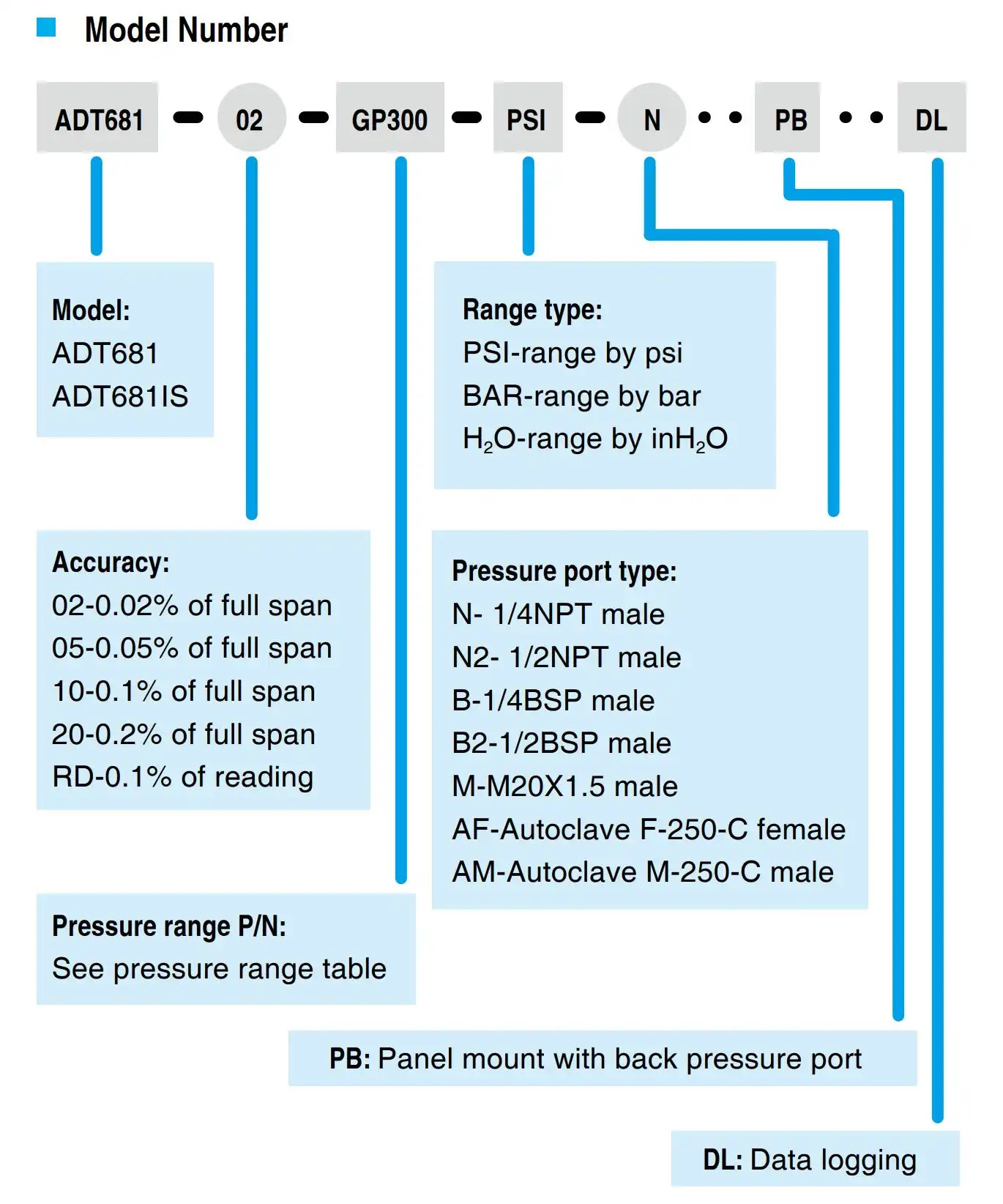

- Panel mount gauges are available (optional)

- Intrinsically safe version 681IS (optional)

- Data logging (optional)

- IP67 rated (681IS)

- ISO 17025-accredited calibration w/data included

With advanced microprocessor technology and state-of-the-art silicon pressure sensors, the 681 series digital pressure gauges provide an accurate, reliable, and economic solution for a wide range of pressure applications. They are loaded with functionality and remarkably easy to use. To reach the best performance, every silicon pressure sensor in our gauges is specially aged, tested and screened before assembly. At Additel, fully temperature compensated accuracy means every sensor is pressure tested at several environmental temperatures from -10°C to 50°C. With this test data individual coefficients are generated and stored in the gauge characterizing its performance over the full temperature compensated range. And now the ADT681IS comes with an IP67 rating meaning it is dust resistant and water proof, submerible in 1 meter of water.

Designed To Fit Your Need

Additel pressure gauges give you the widest variety of sensor choices on the market. Whether you require low inches of water measurement or very high pressure measurement, we have a gauge that will meet your need. We offer sensors which are ±1 inH2O (±2.5 mbar) to 60K psi (4,200 bar) and everything in between.

Do your applications require you to measure both positive and vacuum pressure? Our compound gauges do not compromise accuracy and provide you with the same high accuracy specification on both positive and vacuum pressures. We offer a wide variety up to 300 psi (20 bar). If you need a higher range, just contact us and we can likely customize one to meet your need. We also offer absolute pressure sensors to 5K psi (350 bar) and a full range of differential pressure sensors from ±1 inH2O (±2.5 mbar) to ±300 inH2O (±700 mbar). Are you looking for a pressure gauge to use in hazardous areas? Our certified (ATEX, CSA US & IECEx) intrinsically safe models (681IS) are designed for pressure measurement in hazardous areas.

If you need to panel mount our sensors, we offer the option (see ordering information) for a back-mounted pressure port and gauge housing designed to fit in a panel. And most recently, we've added the option to do stand-alone data logging with the 681. Now you can record more than 21,000 records internal to the 681 series. Each record includes date, time, pressure and temperature readings. Download the logged data with our free Additel/Land software or you can purchase our Additel/Log II for real-time logging and data analysis. The 681 series digital pressure gauges are unmatched in performance and reliability. Best of all, they are very affordable.

Pressure ranges to 60,000 psi (4,200 bar)

0.02% full span accuracy (681-02)

0.05% full span accuracy (681-05)

0.1% full span accuracy (681-10)

0.2% full span accuracy (681-20)

0.1% reading span accuracy (681-RD)

IP67 rated: Submersible in 1 meter of water(681IS)

Fully temperature compensated accuracy from

14°F to 122°F (-10°C to 50°C)

Up to eleven selectable pressure units

Large, easy to read display with 5-digit resolution

Backlit display

% pressure indication with fan-shaped graph scale for

visual reference

Display flash warning when pressure over 120% of FS

Bottom mount or panel mount

ATEX certified intrinsically safe (Model 681IS)

ISO 17025 accredited calibration with data(included)

9V battery power or AC adapter (optional)

Data logging to 21,843 records (includes date, time,

pressure and temperature)

| General Specifications | ||

|---|---|---|

| Model | ADT681 | ADT681IS |

| Description | Digital Pressure Gauge | Intrinsically Safe Digital Pressure Gauge |

| Intrinsic Safety & European Compliance | CE marked | CE marked |

| ATEX certified intrinsically safe | ||

| Ɛx II 1G EX ia IIC T4 Ga | ||

| TUR 16.0023X | ||

| Accuracy (For detailed accuracy, please see pressure range table) | 681(IS)-02 : 0.02% of full span | |

| 681(IS)-05 : 0.05% of full span | ||

| 681(IS)-10 : 0.1% of full span | ||

| 681(IS)-20 : 0.2% of full span | ||

| 681(IS)-RD : 0.02% of full span (0% to 20% of Range), 0.1% of reading (20 to 100% of Range), 0.25% of full span (Vaccuum) [1][2] | ||

| Gauge Types | Gauge pressure, Compound pressure, Absolute pressure, Differential pressure, Barometric pressure | |

| Fan-shaped Graph Scale | Similar to analog dials, including pressure swing, % indication with fan-shaped graph scale for visual reference, low/high alarm | |

| Display | Description: 5 full digit FSTn LCD | |

| Display rate: 3 readings per second (Default setting). Adjustable from 10 readings per second to 1 reading every ten seconds | ||

| Numeral display height: 16.5mm (0.65'') | ||

| Pressure Units | Pa, kPa, MPa, psi, bar, mbar, kgf/cm2, inH2O @4°C, mmH2O @ 4°C, inHg@0°C, mmHg @0°C | |

| Enviromental | Compensated Temperature: 14°F to 122°F (-10°C to 50°C) | |

| Operating Temperature: 14°F to 122°F (-10°C to 50°C) | ||

| Storage Temperature: -4°F to 158°F (-20°C to 70°C) | ||

| Humidity: <95% | ||

| Pressure Port | 15,000 psi: 1/4NPT male, 1/2NPT male, 1/4BSP male, 1/2BSP male, M20x1.5 male | |

| 15,000 psi: 1/4HP female (Autoclave F-250-C, 9/15\" - 18 UNF-2B) or 1/4HP male (Autoclave M-250-C, 9/15\" - 18 UNF-2A)"}">>15,000 psi: 1/4HP female (Autoclave F-250-C, 9/15" - 18 UNF-2B) or 1/4HP male (Autoclave M-250-C, 9/15" - 18 UNF-2A) | ||

| Differential Pressure: 0.236 inch (Ø6 mm) test hose | ||

| Other connectsion available upon request | ||

| Power | Battery: One 9V alkaline battery (included) | |

| Battery Life (High Power Mode): 320 hours | ||

| Battery Life (Low Power Mode): 300 hours (10 readings/s), 500 hours (3 readings/s), or 4000 hours (1 reading / 10s) | ||

| Power auto-off: 60 minutes power auto-off. Auto-off may be disabled. | ||

| External power: 100/220V external power adapter (optional) | ||

| Enclosure | Case material: Aluminum Alloy | |

| Wetted parts: 316L SS | ||

| Dimension: Ø110mm X 35mm depth X 176mm height (panel mount gauge: Ø140mm X 86mm depth) | ||

| Weight: 0.6kg | ||

| Compliance | Protection Level: IP67 (available for 681IS GP15-60K) | |

| Vibration: 5g (20-2000 Hz) | ||

| Shock Resistance: 100g/11ms | ||

| Data Logging (Available with data logging option ADT681-...-DL) | Data storage: 21,843 records (each record includes data, time, pressure, and temperature) | |

| Rate: user -selectable from 1 to 99,999 second intervals | ||

| Communication | RS232 (Do not use the RS-232 connector in a hazardous atmosphere) | |

| Warranty | 1 year | |

| [1] FS = -14.5 psi, [2] Applicable ADT681-RD-CPX | ||

| Gauge Pressure[1] | ||||||

|---|---|---|---|---|---|---|

| P/N | Pressure Range | Media[2] | Accuracy | Burst Pressure | ||

| psi | bar | %FS | %RD | |||

| V15 | -15 | -1 | G, L [3] | 0.02 (0.05, 0.1, 0.2) | N/A | 3× |

| GP2 | 2 | 0.16 | G, L | 0.05 (0.1, 0.2) | N/A | 3× |

| GP5 | 5 | 0.35 | G, L | 0.05 (0.1, 0.2) | 0.1 | 3× |

| GP10 | 10 | 0.7 | G, L [3] | 0.02 (0.05, 0.1, 0.2) | 0.1 | 3× |

| GP15 | 15 | 1 | G, L [3] | 0.02 (0.05, 0.1, 0.2) | 0.1 | 3× |

| GP30 | 30 | 2 | G, L [3] | 0.02 (0.05, 0.1, 0.2) | 0.1 | 3× |

| GP50 | 50 | 3.5 | G, L | 0.02 (0.05, 0.1, 0.2) | 0.1 | 3× |

| GP100 | 100 | 7 | G, L | 0.02 (0.05, 0.1, 0.2) | 0.1 | 3× |

| GP150 | 150 | 10 | G, L | 0.02 (0.05, 0.1, 0.2) | 0.1 | 3× |

| GP300 | 300 | 20 | G, L | 0.02 (0.05, 0.1, 0.2) | 0.1 | 3× |

| GP500 | 500 | 35 | G, L | 0.02 (0.05, 0.1, 0.2) | 0.1 | 3× |

| GP600 | 600 | 40 | G, L | 0.02 (0.05, 0.1, 0.2) | 0.1 | 3× |

| GP1K | 1000 | 70 | G, L | 0.02 (0.05, 0.1, 0.2) | 0.1 | 3× |

| GP1.5K | 1500 | 100 | G,L | 0.02 (0.05, 0.1, 0.2) | 0.1 | 3× |

| GP2K | 2000 | 140 | G, L | 0.02 (0.05, 0.1, 0.2) | 0.1 | 3× |

| GP3K | 3000 | 200 | G, L | 0.02 (0.05, 0.1, 0.2) | 0.1 | 3× |

| GP5K | 5000 | 350 | G, L | 0.02 (0.05, 0.1, 0.2) | 0.1 | 3× |

| GP10K | 10000 | 700 | G, L | 0.02 (0.05, 0.1, 0.2) | 0.1 | 3× |

| GP15K | 15000 | 1000 | G, L | 0.05 (0.1, 0.2) | 0.1 | 2× |

| GP20K | 20000 | 1400 | G, L | 0.05 (0.1, 0.2) | N/A | 1.5× |

| GP25K | 25000 | 1600 | G, L | 0.05 (0.1, 0.2) | N/A | 1.5× |

| GP30K | 30000 | 2000 | G, L | 0.05 (0.1, 0.2) | N/A | 1.5× |

| GP36K | 36000 | 2500 | G, L | 0.05 (0.1, 0.2) | N/A | 1.5× |

| GP40K | 40000 | 2800 | G, L | 0.05 (0.1, 0.2) | N/A | 1.35× |

| GP50K | 50000 | 3500 | G, L | 0.1 (0.2) | N/A | 1.2× |

| GP60K | 60000 | 4200 | G, L | 0.1 (0.2) | N/A | 1.1× |

| [1] Sealed gauge pressure for above 1,000 psi [2] G=Gas, L=Liquid [3] 0.02% FS for gas media only | ||||||

| Barometric Pressure | |||||

|---|---|---|---|---|---|

| P/N | Pressure Range | Media | Accuracy | Burst Pressure | |

| Low | High | ||||

| BP | 60 kPa | 110 kPa | G | 40 Pa | 3× |

| Absolute Pressure | |||||

|---|---|---|---|---|---|

| P/N | Pressure Range | Media[1] | Accuracy(%FS) | Burst Pressure | |

| psi | bar | ||||

| AP5 | 5 | 0.35 | G | 0.1 (0.2) | 3× |

| AP10 | 10 | 0.7 | G | 0.1 (0.2) | 3× |

| AP15 | 15 | 1 | G | 0.1 (0.2) | 3× |

| AP30 | 30 | 2 | G | 0.1 (0.2) | 3× |

| AP50 | 50 | 3.5 | G | 0.1 (0.2) | 3× |

| AP100 | 100 | 7 | G, L | 0.05 (0.1, 0.2) | 3× |

| AP300 | 300 | 20 | G, L | 0.05 (0.1, 0.2) | 3× |

| AP500 | 500 | 35 | G, L | 0.05 (0.1, 0.2) | 3× |

| AP1K | 1000 | 70 | G, L | 0.05 (0.1, 0.2) | 3× |

| AP3K | 3000 | 200 | G, L | 0.05 (0.1, 0.2) | 3× |

| AP5K | 5000 | 350 | G, L | 0.05 (0.1, 0.2) | 3× |

| [1] G=Gas, L=Liquid | |||||

| Differential Pressure | ||||||

|---|---|---|---|---|---|---|

| P/N | Pressure Range | Media | Accuracy (%FS)[1] | Burst Pressure | Static Pressure Range | |

| (inH2O) | (mbar) | |||||

| DP1 | ±1 | ±2.5 | G | 0.05[2] | 100× | ±10 psi |

| DP2 | ±2 | ±5.0 | G | 0.05[2] | 100× | ±10 psi |

| DP5 | ±5 | ±10 | G | 0.05[2] | 50× | ±10 psi |

| DP10 | ±10 | ±25 | G | 0.05[2] | 20× | ±10 psi |

| DP20 | ±20 | ±50 | G | 0.05 | 20× | ±10 psi |

| DP30 | ±30 | ±75 | G | 0.05 | 20× | ±10 psi |

| DP50 | ±50 | ±160 | G | 0.05 | 3× | ±10 psi |

| DP100 | ±100 | ±250 | G | 0.02 | 3× | ±15 psi |

| DP150 | ±150 | ±350 | G | 0.02 (0.05) | 3× | 50 psi |

| DP300 | ±300 | ±700 | G | 0.02 (0.05) | 3× | 50 psi |

| [1] FS specification applies to the span of the range. Accuracy includes one year stability. [2] 0.05%FS accuracy (incl 6 months stability). One year accuracy is 0.05%FS calibration accuracy combined with 0.05%FS one year stability. | ||||||

| Compound Pressure | ||||||

|---|---|---|---|---|---|---|

| P/N | Pressure Range | Media [1] | Accuracy | Burst Pressure | ||

| (psi) | (bar) | %FS[2] | %RD | |||

| CP2 | ±2 | ±0.16 | G | 0.05 (0.1,0.2) | N/A | 3× |

| CP5 | ±5 | ±0.35 | G | 0.02 (0.05,0.1,0.2) | 0.1 | 3× |

| CP10 | ±10 | ±0.7 | G | 0.02 (0.05,0.1,0.2) | 0.1 | 3× |

| CP15 | ±15 | ±1 | G | 0.02 (0.05,0.1,0.2) | 0.1 | 3× |

| CP30 | -15 to 30 | -1 to 2 | G | 0.02 (0.05,0.1,0.2) | 0.1 | 3× |

| CP100 | -15 to 100 | -1 to 7 | G, L | 0.02 (0.05,0.1,0.2) | 0.1 | 3× |

| CP300 | -15 to 300 | -1 to 20 | G, L | 0.02 (0.05,0.1,0.2) | 0.1 | 3× |

| CP500 | -15 to 500 | -1 to 30 | G, L | 0.02 (0.05,0.1,0.2) | N/A | 3× |

| CP600 | -15 to 600 | -1 to 40 | G, L | 0.02 (0.05,0.1,0.2) | N/A | 3× |

| CP1K | -15 to 1K | -1 to 70 | G, L | 0.02 (0.05,0.1,0.2) | N/A | 3× |

| [1] G=Gas, L=Liquid, [2] FS specification applies to the span of the range. | ||||||

| Accessories Included |

|---|

| Rubber boot (Except panel mount) |

| 9V alkaline battery (1 pc) |

| Manual |

| ISO17025 accredited certificate |

| Optional Accessories | |

|---|---|

| 9812 | 110V/220V external power adapter (DC 9V) for 681 digital pressure gauge. |

| 9502 | Additel/Log II real time data logging and graphical software for 681 and 672. |

| 9530-BASIC | Additel/Acal Automated calibration software with asset management, basic version |

| 9530-NET | Additel/Acal Automated calibration software with asset management, network version, Includes server installation and 1 user license |

| 9050 | USB to RS232 (DB9/M) Adapter |

| 9050-EXT | RS 232 (DB9/M) extension cable, 9 feet |

| 9900-681 | Carrying Case for one 681 digital pressure gauge |

| 9902 | Carrying case for 4 gauges |

| 9251 | Rubber boot for ADT681 |

| 9200-681 | Certified O2 Cleaning for ADT681 gauges (some limitations apply) |

| Note: For oil-free applications contact Additel. | |

| Videos |

|---|

| DP Gauge Calibration Video |

| Additel 681 Demo Video |